I have decided to show the train of thought into making an isolated power supply for powering up some small circuits across an isolation barrier.

First attempt

After seeing the voltage feedback circuit from my last post, I am trying out some ideas of using that for an isolated power supply. Here is what I have using LTSpice simulation.

isolated power supply

It is an unregulated isolated power supply from 12V to around 5-6V. There are 3 windings for the transformer on a ferrite.

L1 is feedback path for the oscillator. R4 is used to limit the amount of feedback. L1 is also used as a negative feedback for the voltage across the winding.. The negative peak voltage across the winding is rectified across C4. When the voltage high enough, the 4.5V Zener diode D3 conducts and clamps the base of Q1.

As can be seen from the traces below, the voltage across C4 does not reflect on the output voltage. It regulate the peak voltage of the winding. The voltage regulation of this circuit is about as bad as those old transformer wall warts. The voltage output is about 6.6V at 5mA load and drops down to 5V at 50mA.

The regulation can probably be improved with a bit of components tweaking. A linear LDO regulator at the output can be used for tightening the regulation.

Output voltage (green) vs the feekback voltqge (blue) at C4

L2 is the primary winding for the flyback converter. I limit the inductor current with the help of Q2 and R3. Small inductor value and high supply voltage results in high di/dt. Some of these energy ends up as high voltage spikes at self resonant frequency of component parasitic.

L3 is the secondary winding for the flyback circuit. I use a ferrite bead to filter the switching noise.

I use a RCD snubber in the circuit. It merely clamps the collector voltage of Q1 (rated for VCE = 40V) to a safe value. A RC snubber could eliminate the ringing by dumpling the excessive energy. It is something to think about for EMI reasons.

Q1 collector voltage with and without snubber

Update

I played around with the simulation and tweaked a few values. It seems to me that the voltage feedback limits the power too much such that the output cannot maintain regulation at 50mA load.

I also found some serious problem with the current LTSpice Zener diode database. There are a whole bunch of these in that picture that I didn't highlight. So I wouldn't want to use them without checking their datasheet. I used to use them a few years back without issues. I filed a support ticket with Analog.

LTSpice diode/Zener database

so the "4.5V" is the normal working voltage of the circuit it is supposed to protect not Zener voltage. Its Zener voltage is 6.8V.

At first find the part number a bit funny, but didn't think much about that as the values are what I expected to see. Zener diodes tend to start conducting well before their Zener voltage and aren't very precise and harder to tweak.

Analog feedback

I played around with the design with feedback from the secondary side. The voltage regulation is very tight and virtually stays at around 5V from 5mA to125mA load. I don't know if I can trust the TL431 3rd party behavior model. It is nice but it has too many parts.

Adding analog feedback from across the isolation barrier

Simplifying the design

So far I have been thinking like a typical analog designer adding a piece here and there and tweaking their value. A discrete design is fine to a certain point, but each piece you add increase the complexity and may also suffer from system level interaction. It is time to sit back and approach the problem in a different direction with a blank slate.

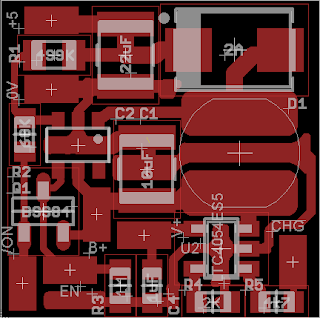

I came up with an unregulated supply using the

MC64063A switching regulator. It has BJT transistor output and slow switching, but it is a cheap switching regulator made by multiple vendors. Having learnt the lesson of chip supply outage, that's one hell of a good reason to at least give it a try.

The MC64063A is operating as an inverting regulator driving the primary winding of the flyback inverter. L1 inductor ramps up and the energy is stored in magnetic field as the driver is on. When the driver is off, the magnetic field collapse and primary side voltage goes from +10V and changes to a negative polarity. Current drain from the inductor through D1 to charge C2. Both windings are magnetically coupled, so the primary winding voltage could be used as a rough proxy of the secondary side.

Note: There are no nasty spikes on the primary side with this flyback circuit. The ringing at the secondary side can be ignored by the rectifier circuit.

However, there is a gotcha. The primary side voltage drops off to a lower point (-2.65V) than the secondary side at the beginning of the cycle that C2 is being charged. The voltage across C2 is what the MC64036 is regulating to.

Voltage waveforms: Primary side (Green) and Secondary side (Red)

The following waveform shows the rectifier currents on both sides. I use a BJT Q2 as a synchronous rectifier for the output. I have tried both a Schottky diode or a MOSFET and the BJT turns out working better. It has low drop (0.187V at the current peak), but slow enough without adding ringing from self resonant. The negative spike at the left side is also ignored by Q2.

Diodes waveforms: Primary side (Blue), Secondary side (light blue)

Note: D1 conducts at the lowest point in the primary side which is a not a perfect symmetry point in the waveform.

1K load: 4.85V

100R load: 4.31V

Load regulation isn't great, but it is good enough to be used with a LDO.

I found some decent isolation for coupled inductor. e.g. Bourns SRF0703 series with 500V RMS Hi-pot.