Go to Timer V1

|

| Timer V2 |

There were a few changes to the V1 design.

Supercap backup power

Connectors for LED/sensor and Servo connector

Switcher module

LCD and buttons I/O changes. LCD backlight on/off control by ambient light

I2C connector

expansion connector for nRF24 (no firmware support)

Supercap backup power

The backup circuit is similar to the one I have been using in my digital clocks. I added the option of using a constant current source for charging the low ESR supercap. The resistor is simpler and have one less diode drop.

Servo connector

It turns out that the water pump I originally used wasn't reliable, so I have been using a servo driven valve. I had to rerouted the control line for power supply the servo.

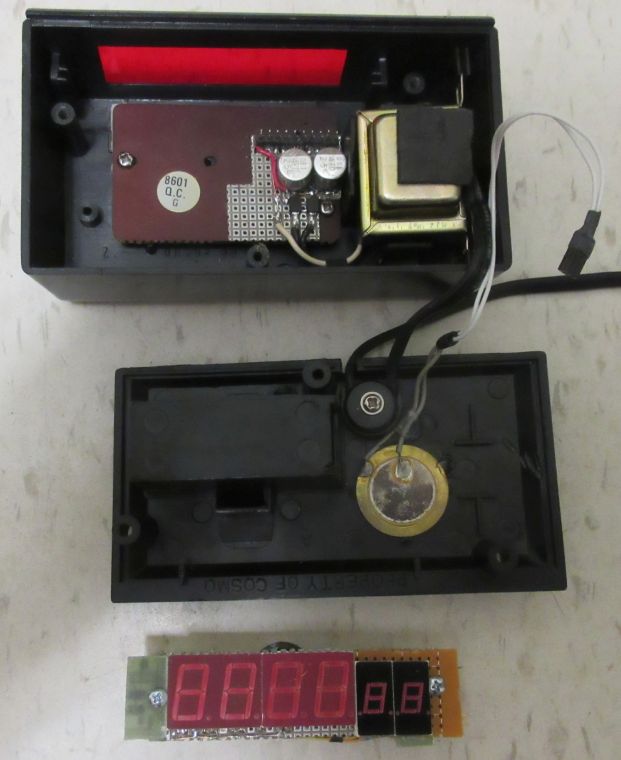

Switcher module

|

| 5V supply |

A DC-DC converter module is used for converting the 12V to 5V for the timer and servo. I used a 10K resistor to set the output of the KIS-3R33 module to 5V. Other modules can be used.

I am using power supply grade Tantalum capacitors as they take up less heights and offers a longer lifetime than electrolytic capacitors. The DC-DC module operates at 340kHz which helps to reduce the capacitance.

LCD and buttons I/O changes

I have decided to use time delay instead of polling for Busy Flag for the LCD. This frees up 1 GPIO pin and simplifies the sharing of the LCD I/O signals for multiple functions.In the V1 design, an ADC channel is used for sensing the buttons. The LCD data lines now are used for polling the buttons.

|

| nRF24 module |

Also new in this version is a connector for a nRF24 module. The module uses SPI which shares the same data lines with the LCD.

github: https://github.com/FPGA-Computer/Timer